45 zebra s4m label alignment

Zebra Printer Skipping Labels | MIDCOM Data Technologies Load your Zebra printer with labels for your application. Power on your Zebra printer. Press and hold the Feed Button until it flashes two times, and then release it. Allow your Zebra printer to complete feeding labels and printing a sensor profile. Your Zebra printer should now be calibrated. Positioning the Label Sensor for Unique Labels | Zebra Align the red light with an area of the label that allows the sensor to view a consistent inter-label gap (2 - 4mm, 3mm recommended). As shown in Figure 1, the sensor is positioned on the jewelry tag at the point it can see the standard 3mm inter-label gap and avoids the wider spacing of the middle of the label.

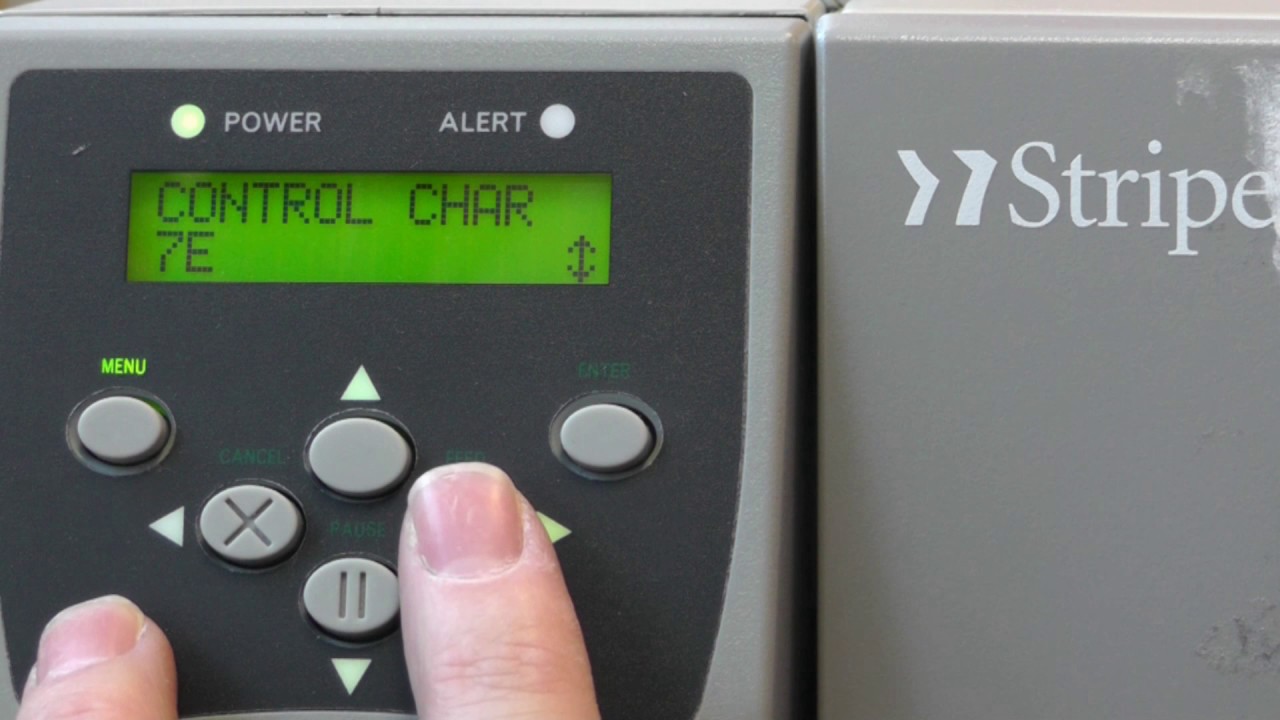

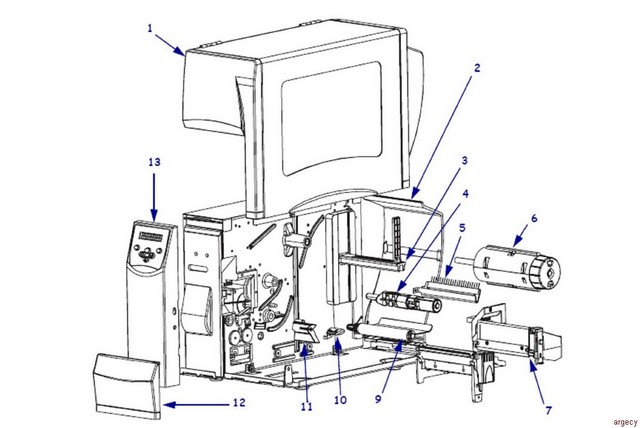

PDF S4M Control Panel Maintenance Kit - Zebra Technologies 10/3/05 S4M Installation Instruction 20060L-001 Rev. A Remove and Install the Electronics Cover 1. Turn Off (O) the printer and disconnect the AC power cord and all data cables. 2. Open the media door and remove the media and ribbon. 3. See Figure 2. Remove the electronics cover mounting screw and washer and then close the media door.

Zebra s4m label alignment

POS FAQ Why are my labels not lining up on the tear - POSGuys With Zebra label printers, power off the printer, and hold the feed button down. Power the printer back on, and after the feed light blinks twice, release the feed button. The printer should begin the calibration stage, and will eject several labels before being calibrated. Once calibration is finished, the labels should be properly aligned. PDF Z Series and S4M Platen Roller Maintenance Kit - Zebra Technologies Remove the Platen Roller Pulley and Belt Z Series and S4M 1. See Figure 6. Loosen the stepper motor locking screw and pivot screw. Remove the drive belt from the stepper motor. Figure 6 • Stepper Motor Pivot Screw and Locking Screw 2. Pivot up the stepper motor and remove the drive belt. 3. Loosen the two set screws on the platen pulley. 4. Zebra S4M Barcode Label Printer - Barcodesinc.com The Zebra S4M is designed for budget-minded users who need maximum production.The S4M features both 203 and 300 dpi print resolutions, multiple interface options (including serial, parallel, USB, Ethernet and 802.11b wireless connections).The side-loading design makes adding labels and ribbon fast and easy, and a full 8" label roll capacity means refills are needed less often.

Zebra s4m label alignment. Zebra S4M Thermal Label Printer - Cadgulf For both thermal transfer and direct thermal printing at a cost-effective price, the Zebra S4M is the ideal choice. Since we are an certified Zebra Partner in Dubai, UAE with robust in-house IT support. CAD Gulf LLC can provide you with best Zebra Label Printer price in Dubai, UAE with installation and annual maintenance support. For inquiries ... TOP 5 Common Issues With Zebra Thermal Printers and How To Fix TOP 5 Common issues with zebra thermal printers and how to fix. Poor Print Quality. Skipping Labels. None of the settings save. Wrong type of ribbon and paper. Poor or low barcode ANSI grade. During my 20 years of troubleshooting zebra printers, I have found that the same problems arise over and over again. ZP Series: Calibrating the Printer - Zebra Technologies Procedure: Load the printer with the labels for your application. Power on the printer. Press and hold the Feed Button until it flashes quickly two times then release the Feed Button (it is a flash sequence, you can see one flash, then two quick flashes, after that release the Feed Button). Allow the printer to complete feeding labels and print ... zebra printers - How to center text in ZPL language? - Stack Overflow If mm is used ( ^MUm) the center-thingy does NOT work properly (tested on labelary.com and Zebra S4m). Use ^FB to define a Field Block. From the manual: The ^FB command allows you to print text into a defined block type format. This command formats an ^FD or ^SN string into a block of text using the origin, font, and rotation specified for the ...

Zebra S4M User Manual - Calibrate the Printer - manualsdir.com During auto calibration, the printer determines the label length and sensor settings. The results of the auto calibration are stored in the printer's memory and ... How do I change the label size settings for my Zebra printer? You may also need to change the label size settings for your Zebra printer in the Printing Defaults section. 1. Click [ Advanced ]. 2. Click [ Printing Defaults... ]. 3, Under Size, change the label size to match with your thermal labels. You can change the unit under Paper Format, if required. Click [ OK] once you are done changing the label ... SOLVED: Can't get the Zebra S4m printer to align? How - Fixya 8 Aug 2011 — Can't get the Zebra S4m printer to align? How should I trouble shoot this? Sonya - Zebra S4M Thermal Label Printer question. S4M Initial Printer Setup Details and ... - Zebra Technologies Jan 31, 2020 · The S4M printer comes from the factory set to tear-off mode and adjusted for full with paper label stock with wax ribbon. Many printing applications will function with these factory settings and require no additional adjustments beyond the communications setup and minor darkness adjustment.

Label Rotation and Orientation for ZPL based ... - Zebra Technologies To invert the entire label 180 degrees, refer to the ^PO command in the ZPL Manual . Text and barcode orientation can be changed according to preference and the choices are: Normal Rotated 90 degrees (clockwise) Inverted 180 degrees Read from bottom up, 270 degrees For the specific text or barcode command, refer to the ZPL Manual . Zebra S4M - Troubleshooting - FogBugz Check that the labels and ribbon are loaded correctly. The label sensor is the black slot along the back wall of the printer. Make sure labels are passing through this slot, and that the metal guide is snug against the labels. (Push down on labels slightly, and slide guide so that it is resting on top of the edge of the label stock) PDF Take Label Sensor - support.zebra.com 10/3/05 S4M Installation Instruction 20065L-001 Rev. A Install the Take-Label Sensor Board 1. See Figure 6. Align the take-label sensor board with the two guide posts and install it on the posts, ensuring the posts are inserted in the board. Figure 6 • Install the Take-Label Sensor Board 1Control Panel 2Take-Label Sensor Board 3Mounting Screws (2) Video: Calibration Issues on ZM-Series - Zebra Technologies The black mark must be located on the inboard side of the label since this sensor is fixed in position and mounted against the inner wall. 3. Positioning the moveable sensor The moveable or adjustable position sensor must be placed so the top of form can be detected. This can be an inter-label gap, a hole or notch.

Adjusting Left Position and Top Position of the Zebra Barcode Printers All ZPL Zebra Barcode Printers except the 2824 Series, 2844 Series, S4M (E53 Firmware Version), 888 DD/TT Series, MZ Series, ZQ110, EM220, and EM220II. resolution / answer It is recommended to correct the issue of label objects printed on the incorrect location of a label within the software or application rather than adjusting the left ...

How to adjust the tear off position on a Zebra ZT610 | Smith Corona Labels Contact us at 1-800-875-7000 or Tired of your thermal label not tearing on the perforation? In this video, we give you step-by-step directions on how to adjust the tear...

Unique Label - Zebra Technologies S4m and ZT200-Series Transmissive Sensor S4M and ZT Transmissive Sensor is a fixed position style and is used when the reflective sensor fails to function reliably with a gap label. ... Align the red light with an area of the label that allows the sensor to view a consistent inter-label gap (2 - 4mm, 3mm recommended). As shown in Figure 1, the ...

c# - How can I center text for a label being printed on a Zebra ZXP ... You have to use the DrawTextEx () method and pass it in the alignment parameter. (Note this method is not provided in the SDK but it does exist in the DLL! You need to add it in your application to get it to work) 3 = left justified. 4 = center justified. 5 = right justified. Add this code to the ZBRGraphics.cs file.

Auto Calibration Manual Calibration - Zebra Technologies reflective sensor detects the start-of-label indicator (the notch, hole, black mark, or gap between die-cut labels). With both continuous media and non-continuous media, the sensor detects an out-of-paper condition. If you have difficulties with calibration while using this sensor, use the transmissive sensor (see Select the Media Sensor onpage62).

S4M Printer -- Resolving Print Quality Issues - Zebra Technologies Most often it is set to the full width and the label format determines the printed area based on the image location. Applications and drivers may set a print width and reduce the printable area based label size. This is not a problem unless one attempts to print outside the previously restricted area.

PDF Select or Adjust the Media Sensors - Zebra Technologies 13290L-004 Rev. A S4M User Guide 6/15/09 MEDIA TYPE Set Media Type Tells the printer which type of media you are using. Selections: • GAP/NOTCH—Use for non-continuou s web media, non-continuous fanfold media, and tag stock. • CONTINUOUS—Use for media that does not have divisions between labels. • MARK—Use for non-continuous black ...

How to solve Zebra thermal label printer problems in ten seconds Hold down the button until the light flashes five times, then release it. This will make the printer enter label width calibration. It will print a series of widths, getting wider each time, on a label. When the printed width matches the label width (or your preferred setting), tap the button once to lock it in.

S4M Industrial Printer Support & Downloads | Zebra S4M Industrial Printer Support This printer is discontinued. We may offer drivers, firmware, and manuals below for your convenience, as well as online tech support. If you require additional support, please contact a Zebra Authorized Service Provider. Printer Discontinuation Date: July 31, 2013

Adjusting Left Position and Top Position on Zebra Barcode Printers 105SLPlus Industrial Printers. 110PAX Print Engines (disc.) 110Xi4 Industrial Printer. 140Xi4 Industrial Printer. 170Xi4 Industrial Printer. 220Xi4 Industrial Printer. 2824 Plus Series. 2824-Z Series. All Surface RFID Label Solution.

S4M User Guide - Zebra Technologies Zebra Technologies Europe Limited Zebra House The Valley Centre, Gordon Road High Wycombe Buckinghamshire HP13 6EQ, UK T: +44 (0)1494 472872 F: +44 (0) 1494 450103 T: +44 (0) 1494 768298 F: +44 (0) 1494 768210 Germany: Tsgermany@zebra.com France: Tsfrance@zebra.com Spain/Portugal: Tsspain@zebra.com All other areas: Tseurope@zebra.com

PDF S4M User Guide - Zebra Technologies I have determined that the Zebra printers identified as the Stripe™ Series S4M manufactured by: Zebra Technologies Corporation 333 Corporate Woods Parkway Vernon Hills, Illinois 60061-3109 U.S.A. Have been shown to comply with the applicable technical standards of the FCC For Home, Office, Commercial, and Industrial use

Label Alignment - BarTender Support Portal To do this in BarTender, select the "File>Print" menu item from your loaded label design, and from the Print dialog click the "Document Properties" button. In the printing preferences of the printer driver dialog that opens, select the "Stock" tab and choose "Transmissive" for the sensor type.

Zebra S4M user guide - YouTube Zebra S4M Thermal Printer user guide by Touchretail. This video covers the following topics: Part 1 - Loading Labels & Ticket stocks Part 2 - Aligning Media & Sensor guides Part 3 - Loading Thermal...

Zebra S4M Series Manual Calibration - YouTube About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features Press Copyright Contact us Creators ...

Video: Calibrating Media on S4M Printer - supportcommunity.zebra.com This procedure will help understand printer setup and configuration for accurate calibration/registration of your labels. This includes: Identifying the media being used Correctly configuring the printer for Black Mark, or Gap media Selecting the correct sensors for the media being used

How to Calibrate a Zebra Printer - ShipWorks To calibrate, find your model of Zebra printer and follow these steps: Zebra ZD420 - SmartCal Media Calibration. Make sure media is properly loaded, the printer cover is closed, and the printer is powered on. Press and hold the PAUSE + CANCEL buttons for two seconds. The printer will feed and measure several labels.

Zebra S4M Barcode Label Printer - Barcodesinc.com The Zebra S4M is designed for budget-minded users who need maximum production.The S4M features both 203 and 300 dpi print resolutions, multiple interface options (including serial, parallel, USB, Ethernet and 802.11b wireless connections).The side-loading design makes adding labels and ribbon fast and easy, and a full 8" label roll capacity means refills are needed less often.

PDF Z Series and S4M Platen Roller Maintenance Kit - Zebra Technologies Remove the Platen Roller Pulley and Belt Z Series and S4M 1. See Figure 6. Loosen the stepper motor locking screw and pivot screw. Remove the drive belt from the stepper motor. Figure 6 • Stepper Motor Pivot Screw and Locking Screw 2. Pivot up the stepper motor and remove the drive belt. 3. Loosen the two set screws on the platen pulley. 4.

POS FAQ Why are my labels not lining up on the tear - POSGuys With Zebra label printers, power off the printer, and hold the feed button down. Power the printer back on, and after the feed light blinks twice, release the feed button. The printer should begin the calibration stage, and will eject several labels before being calibrated. Once calibration is finished, the labels should be properly aligned.

Komentar

Posting Komentar